BS EN10241 fittings (formerly BS1740/1387) have been used over many decades as a strong and reliable method of connecting tubes used to convey air, steam, water and a variety of other liquids.

- Female threads are BSP parallel, male threads are BSP taper to ISO 7-1 (except for longscrews and running nipples where parallel threads are to ISO 228-1).

- Fittings are produced from mild steel forgings, solid bar or tube.

- Available as self colour or with zinc protective coating.

- Self colour fittings are suitable for welding.

- Zinc protective coating can be hot dip galvanising (minimum average coating 55µm) or Delta Protekt zinc flake.

- Only self colour fittings should be used with steam.

- A letter of conformity is available for all items on request.

- Fittings are capable of withstanding the following internal hydrostatic test pressures at ambient temperature:

- Tubulars – 50 bar

- Fabricated fittings – 75 bar

- Seamless fittings – 150 bar

- The method of manufacture for each item is colour coded on our data sheets:

Blue = Tubular

Black = Fabricated

Red = Seamless

Because the standard only gives design test pressures and makes no reference to safe working pressures or temperatures, we have undertaken our own research. We recommend fittings made from solid bar or forgings for use at pressures up to 25 bar and temperatures up to 220° C. They are suitable for use with steam, water, gas and air. However, the effectiveness of the joint is very dependent on size, local service conditions, support conditions and jointing compounds and techniques.

BS EN10241 square head plug

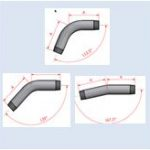

BS EN10241 spring bends

BS EN10241 socket unions

BS EN10241 running nipple

BS EN10241 round caps

BS EN10241 reducing tees

BS EN10241 reducing sockets

BS EN10241 Reducing hex bushes

BS EN10241 male/female elbows

BS EN10241 longscrew connectors

BS EN10241 hex plugs

BS EN10241 heavyweight sockets full and half

BS EN10241 heavyweight barrel nipples

BS EN10241 equal hex nipples

BS EN10241 close taper nipples

BS EN10241 backnuts

BS EN10241 90 degree bends

BS EN10241 90 deg elbows, equal tees, crosses

BS EN10241 45 degree elbows